페이지 정보

B300P/B400P

B300P/B400P

본문

As the product packaging unit is located on the front side for more convenient operation, and the driving unit is located on the back side of the machine, the maintenance is much easier. In addition, it is easy and simple to operate, and it is possible to quickly change products with a minimum of tools and designed to accommodate various selection devices such as inspection and printing machines.

The panelboard is installed on the back of the machine and designed as a door type for convenient maintenance. Because it is equipped with a PLC-based central touch screen that provides the optimal state according to the driver's needs, operation for high-speed production of products is possible on the touch screen, and the transfer and adjustment by the SERVO motor are automatically performed accordingly.

There are few types of molds, and those are light and compact, so it is convenient for replacement. In addition, it is designed to be linked with a cartoner and realize full automation of mass production. It has been designed with a structure that ensures operator safety complying with CE regulations.

Machine

Feature

All machine components that directly contact with the product use parts and materials that comply with current food hygiene and safety regulations (SUS 316L & etc.)

Balcony type design for convenient operation and maintenance

Design that minimizes gaps between assembly connection sections

Improved the accuracy and speed of each part of the machine through the implementation of servo drive technology

Realized user convenience through touch screen operation

Access to step-by-step data value by password input

Round-type chassis, safety cover (PC material) and interlock structure for operator’s safety

Quick and easy change part replacement

cGMP applied design

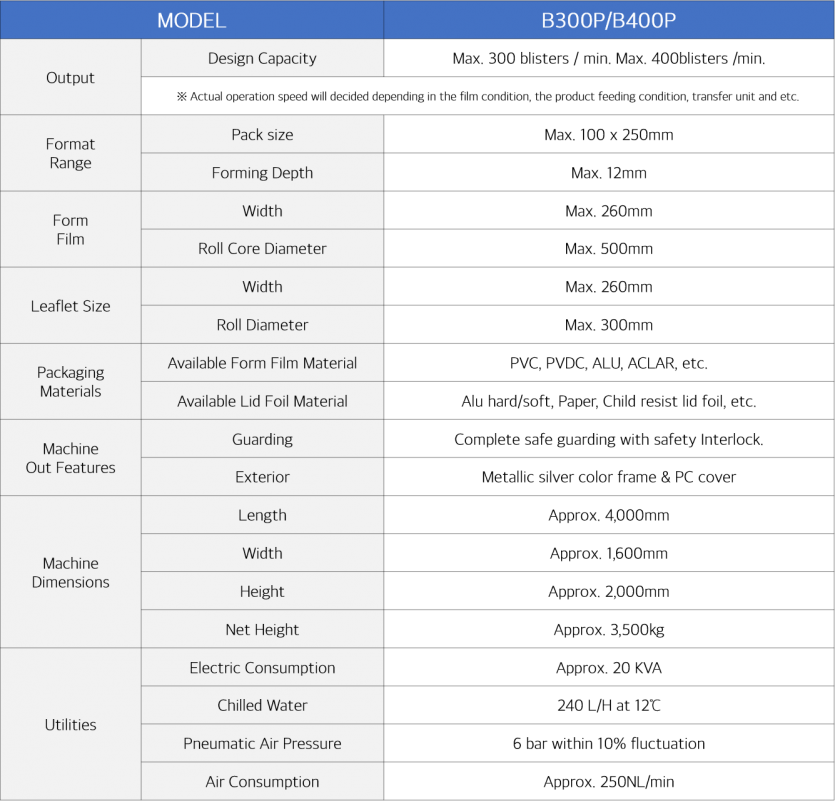

Technical

Specification

댓글목록

등록된 댓글이 없습니다.

PACTRION 47, Gajeong-ro 37beon-gil, Seo-gu, Incheon, Republic of Korea

Company Registration Number 140-10-28488

PACTRION 47, Gajeong-ro 37beon-gil, Seo-gu, Incheon, Republic of Korea

Company Registration Number 140-10-28488