페이지 정보

T5/T8

T5/T8

본문

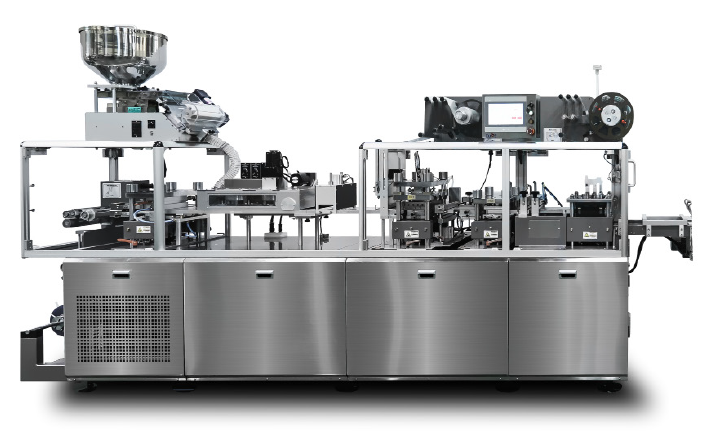

It operates by intermittent operation and consists of a structure that automatically forms, feeds drugs, heats, inspects, seals, cuts, and punches one or several packs at every stroke to discharge the completed product.

The packaging capacity of the machine varies greatly depending on the type of product to be feed and the feeding method. For example, if the product to be feed is a tablet (coated tablet or uncoated tablet), it can be packed at a capacity of about 30-40 strokes per minute. The rotation speed of the machine can be easily selected by operator, and the amount of conveying material can be freely adjusted. In addition, it is configured to be operated conveniently by the monitor of the operation panel, and a pack alignment device for connecting to the next process, a cartoner, can be attached.

The safety device is an important part of controlling the operation of the machine and is built into the element by element, so it must be operated as indicated on the monitor of the operation panel, and the Safety Interlock System is basically configured to stop the operation of the machine immediately when the safety cover is opened.

Machine

Feature

All machine components that directly contact with the product use parts and materials that comply with current food hygiene and safety regulations (SUS 316L & etc.)

Accurate angle division and operation by encoder adjustment of the main shaft

Realized user convenience through touch screen operation

Access to step-by-step data value by password input

Safe and easy maintenance by precise separation of electrical wiring and pneumatic hoses

Available to adjust via digital indicator for the position of all work stations

Round-type chassis, safety cover (PC material) and interlock structure for operator’s safety

Torque limiter for overload protection

Quick and easy change part replacement

cGMP applied design

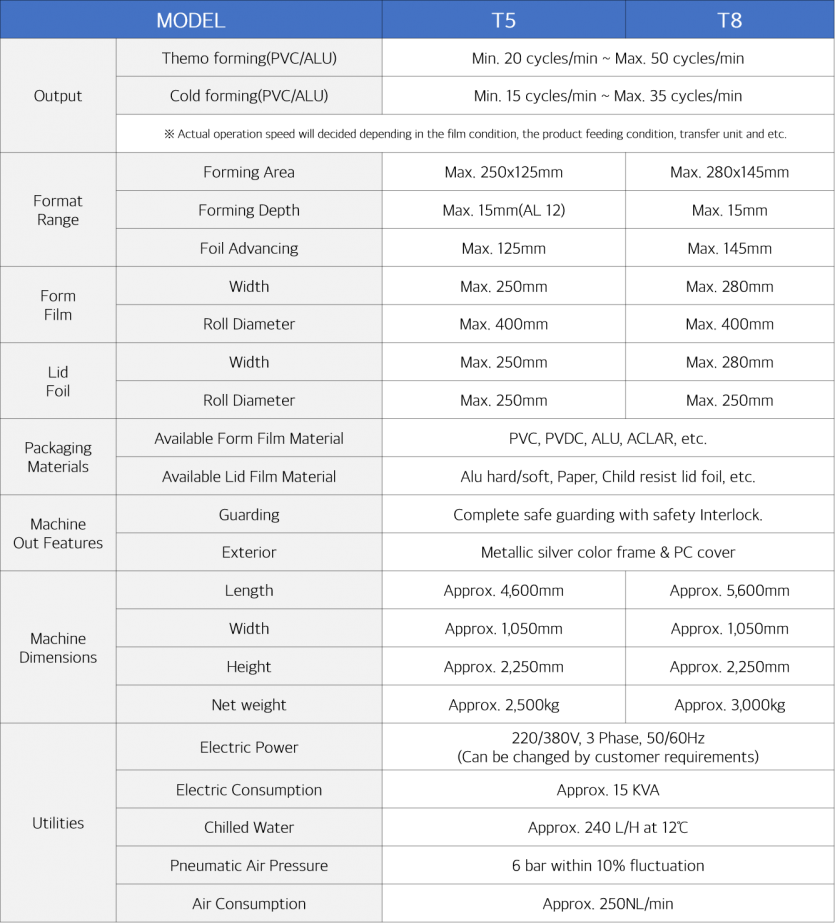

Technical

Specification

- 이전글T6/T6W 21.12.06

댓글목록

등록된 댓글이 없습니다.

PACTRION 47, Gajeong-ro 37beon-gil, Seo-gu, Incheon, Republic of Korea

Company Registration Number 140-10-28488

PACTRION 47, Gajeong-ro 37beon-gil, Seo-gu, Incheon, Republic of Korea

Company Registration Number 140-10-28488